Below you can find a virtual city of an asphalt Plant. There are several Pictures and also exact Procedure of Mixing Asphalt in a Batch Plant. We assume that you are familiar with words like( Asphalt, Mixing aggregate, batch Plant, and Etc), So for more convenience we jump this step and go to the start the description of a Batch Plant .

Types of Plant: |

There are two basic types of plants used to manufacture Hot Mix Asphalt - Batch Plants and Drum Plants. Both plants are capable of producing quality HMA.

1. Batch Plant 2. Drum Plant

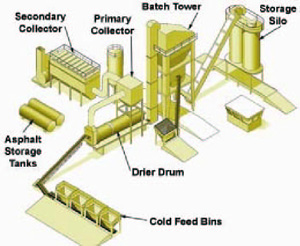

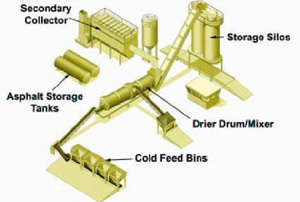

General Features of Plants: There are many components common to batch and drum plants as can be seen Below. These includes:

|

1.Batch Plant Structure 2.Drum Plant Structure

Material for Plants (Aggregates):Aggregate Storage: HMA ( Hot mix Asphalt ) is a mixture of aggregate (crushed stone, gravel, and sand), and asphalt binder. Aggregates are usually stored in stockpile Called Horizontal Stockpile. Stockpiles may be covered to prevent rain from soaking the aggregate or aggregates may be stored in large silos or bunkers. When storage silos or bunkers are used they often act as cold feed bins to meter the aggregates into the plant. 1.HorizontalStockPile 2. Aggregate Silo

3.Bunker Pile |

Where Does Aggregate Goes?Cold Feed Bins: Aggregates are typically moved from the stockpiles to the cold feed bin using a front-end loader. Cold feed bins are used to accurately meter the different aggregates used in the mix to the drying drum. The amount of each aggregate is controlled by a combination of the gate opening at the bottom of the bin and conveyor belt speed.

|

1.Cold Bin 2. Cold Bin Structure

How Transfer the Aggregates to the Bin?A conveyor below the cold feed bins transfers the aggregate to the dryer where the aggregate is dried and heated. Because drum plants produce mix continuously, a weigh scale is used to weigh the aggregate before it enters the dryer so the amount of asphalt binder can be accurately added.

|

1. Feeding system 2. Feeding System Structure

What Happens to the Aggregate after transferring to the Drum? |

They will dry in Dryers to be prepare for mixing and making the asphalt.

Types of Dryers: Aggregates are dried and heated in a dryer drum as they are tumbled through a hot air stream. The hot air is created by a burner and is pulled through the drum by a fan.

The direction of air flow relative to the direction of aggregate flow describes the two types of dryers-Parallel-Flow and Counter-Flow. In a parallel-flow drum aggregates move in the same direction as the hot air. For a counter-flow plant the aggregates moves in the opposite direction.

1.Parallel Dryer 2. Counter Dryer

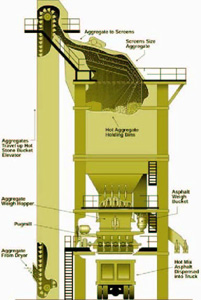

And then what does it do after drying?Will go to Emission Control System:As hot air passes through the aggregate it picks up some fine sand and dust particles. These particles are removed by the emissions control system before the air goes into the atmosphere. Most plants have primary and secondary collectors to remove these particles.The fine sand and some dust is collected in the primary collector and returned to the mix. The secondary collector removes the remaining fine dust. In most cases this dust can also be returned to the mix.

1. Drum Batch Mixer 2. Batch Plant Mixer |

Really what is the difference between Batch Plant and Drum? |

After the aggregate has been dried and heated the difference between batch and drum plants becomes clear.

Batch Plant:

In batch plants the dried hot aggregates exit the dryer and travel up a bucket elevator to the batch tower, where they are separated by size over screens and stored in hot bins. The amount of each aggregate is accurately proportioned by weight in the aggregate weigh hopper. (Picture No,1)

1. Batch Plant (a) 2.Batch Plant (b)

After the Aggregates have been weighed they are dropped into the pug mill where they are mixed with the asphalt binder. The amount of asphalt added to the aggregate is measured either by a weigh bucket or by a pump and meter system. After the asphalt and aggregate are mixed they are either deposited in a truck or in a storage silo.

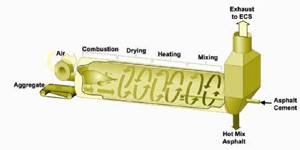

Drum Plant

The mix is made continuously in a drum plant. Asphalt and aggregate are mixed in the drum after the aggregate has been dried and heated. The asphalt is added to the aggregate where the air stream is cooler. After the asphalt and aggregate are mixed they are moved to a storage silo where the mix is loaded into trucks.

1. Parallel Drum Plant

What need Drum Plant? |

1.Multiple Silo 2. Portable Silo

What remains else? |

1. Computer Room For Controlling the Mix

1. Computer Room For Controlling the Mix

And? |